All-welded plate heat exchanger fixture

Read the number:(3862) Time:2014/3/9 18:48:59

All-welded plate heat exchanger plate beam welding jig quick development of self-positioning

http://china.toocle.com 2009 年 12 月 01 日 10:10 Chinese heat exchanger network

Social business Dec. 1 news

Guoco Li, Xue Jin, Zhang Donghua, Yue Bin, tube red, Toby Abstract: The all-welded plate heat exchanger in the manufacture of self-positioning quick jig solves prone positioning inaccuracy when plate beam welding, soldering seam quality is poor, there is no interchangeability fixtures and low productivity problem. Keywords: plate heat exchanger; plate beam; positioning; fixture CLC: TE 965; TQ 05015 Document code: A

In the all-welded plate heat exchanger fabrication, welding plate beam is an important part of the quality assurance equipment, which are mostly used austenitic stainless steel plate beam sheet thickness less than 1 mm in the group and then punched into welded plate. The existence of easily burn, large deformation and poor weld problems in the welding process. In the length of 2 000 mm above the weld, harder to remove such defects. The main factors affecting the quality of beam welding plate has a gap between the plates, stamping deformation, the wrong side and cut burr. To eliminate these problems, it is necessary to improve the positioning accuracy of the fixture. This paper presents a positioning accuracy, ease of operation of self-positioning quick jig.

A structure and principle

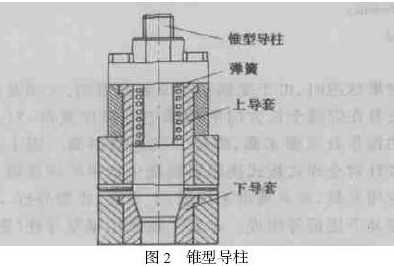

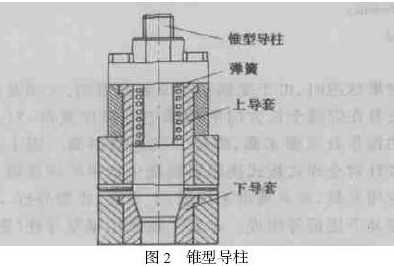

When a higher degree of automation of welding laser welding, TIG or MIG welding, etc., on the degree of automation required fixture also rise. Pneumatic, hydraulic or electrical components to achieve control to improve efficiency in most cases. Length welds on the original size of the plate and the flatness demanding, for some special molding plate, traditional fixture difficult to meet the requirements, such as plate-shaped bulb is dense, due to limited space location , pneumatic and hydraulic clamps in the direction of full-length welds precise positioning complicated operation, the operation of the high technical requirements for workers, weld secondary high failure rates. Figure 1 is a special fixture author for all-welded plate heat exchanger manufacture welded plate beams designed by the upper plate of the fixture, the guide sleeve, tapered pillar, under the guide sleeve and lower platen and other components. This set of tooling using conical pillar (Fig. 2)

Achieve self-positioning, conical pillar interior cavity of the guide sleeve has a small spring, the spring can be achieved when positioned on the platen cushion fall to prevent damage caused by the impact of the plate, the spring allows flexible tooling alignment, so self-positioning. To ensure the accuracy of positioning the central plate is also provided with the three pairs of press-molding the plate shaped exactly like a small block, to limit the relative displacement of the sheet. So just make sure four conical pillar positioned correctly, it will be precise positioning plate. The positioning accuracy of fault 6 000 mm side length is less than 0. 1 mm.

And replacement of board chucking films, lifted by crane to the plate after plate to be positioned to control the crane inching down on the platen, four conical pillar and under the guide sleeve can be completed with a second installation card , each installed card takes less than 1 min, chucking process is simple and efficient. The quality of light can be used to protect tooling strong nylon rope when lifting.

2 Features (1) protection board beam, while the high quality of the welding seam welded portion extends only fixture 1. 5 mm, close to the weld area and tooling materials using different materials QT42210, prevent welding spatter welding slag hurt plate beam, while the rapid proliferation of post-weld heat, reduce the heat-affected zone to prevent the overall deformation plate beam. Due to extremely high accuracy positioning tooling, welding specification choice under appropriate circumstances weld without burn-through, undercut and undesirable phenomena such as molding, rear beam overall shape deformation is very small. (2) less investment, good interchangeability due in the course of the fixture is not to put too much load, so the fixture is mostly Q2352A manufacturing site near the weld plate using the same form of corrugated iron gibs. Corrugated sheet for different forms of the fixture frame does not move, only the replacement of cast iron and the suppression of mold inserts a small module can be based on the same wave form. Such investment in a set of frames, you can complete the welding specifications sheet. (3) simple structure, good stiffness, good manufacturing processes the entire fixture without special structure, there is no large parts, simple structure, the use of truss principle, the two main pressure of the middle with angle triangle structure is welded to improve fixture stiffness to ensure that the fixture is not deformed during use. Framework as a whole or sub-welded, and then the whole process can be. 3 Conclusion

This set of clamps to solve the all-welded plate heat exchanger plate imprecise positioning beam welding process, the weld quality is poor, there is no interchangeability fixtures and low productivity problem. In the high degree of automation, the investment is not large but it can achieve precise positioning of the condition and improve efficiency.

China HVAC Network: http://www.cnhvacrnet.com/detail/4893101.html

Chinese heat exchanger network: http://www.31hrq.com/detail/4893101.html